Liquid Filling Systems

Filling systems fordust and granule materials different type of filling processes are applied according to the materials types and filling constructions; weighing into a container and emptying, weighing during discharging, discontinuous weighing and totalizing, etc…

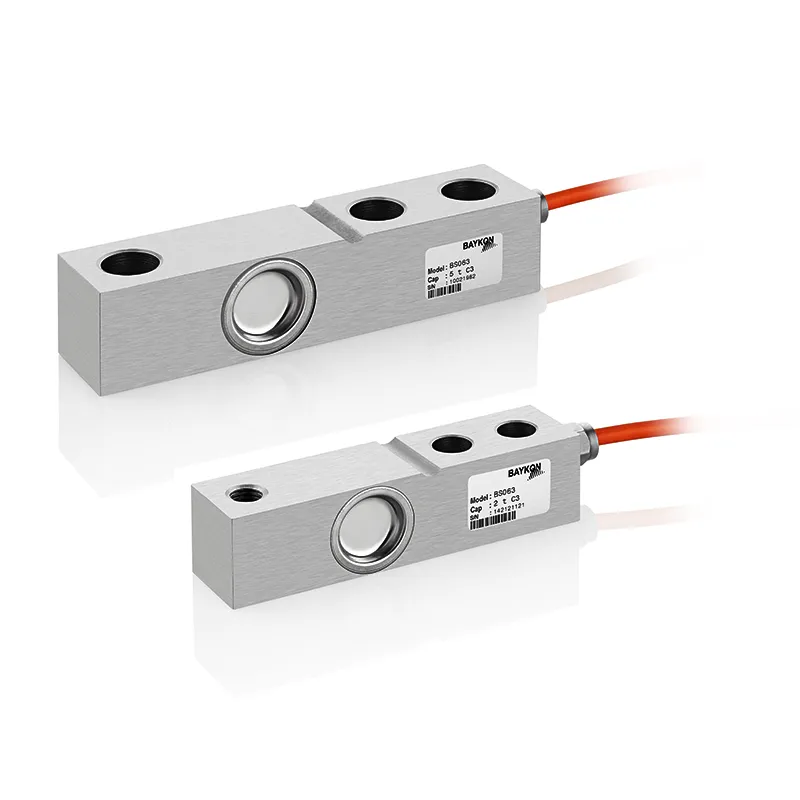

Based on its know-how, technical experience and powerful products portfolio, BAYKON will develop you the best solution.

EU MID approved, legal for trade pail, drum and container filling systems.

BAYKON offers you high-performance filling terminals and optimum solutions for your liquid and dust weighing needs:

-Adaptive Filling Control; Material flow changes because of temperature, viscosity or level changes is traced and cutoff values are automatically compansated.

-Accurate, fast and repeatable filling

-Direct connectivity to PLC’s via fieldbus interfaces.

-EU MID legal for trade approval

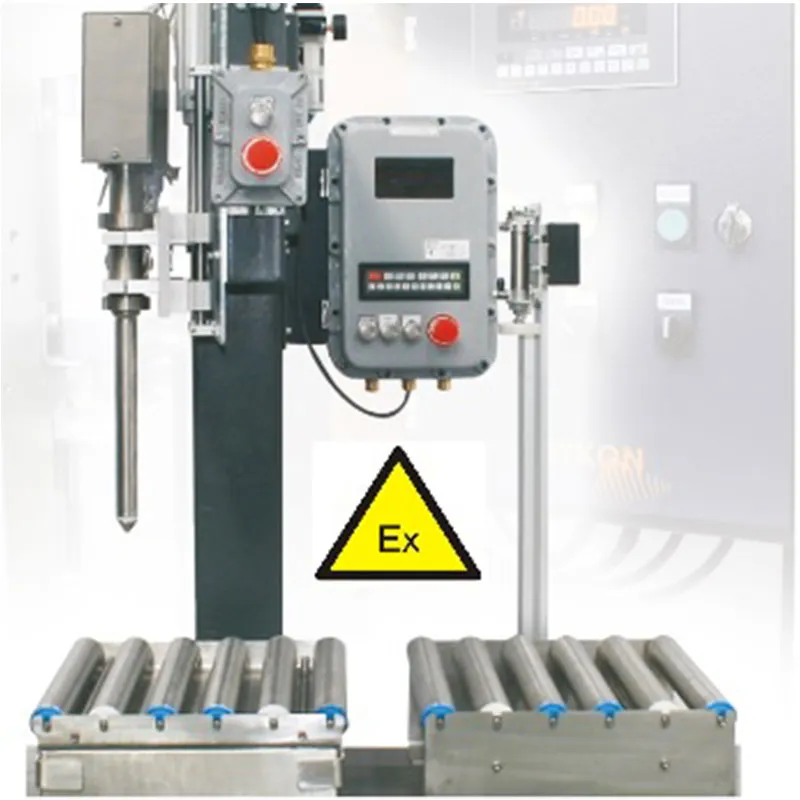

-ATEX approved systems for hazardous areas.

Highlights

Functional Features

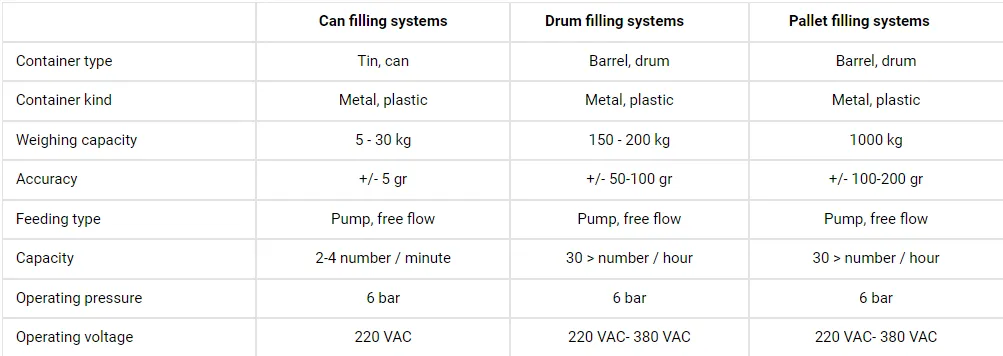

Can filling systems

- Very cost-effective solution for can filling operations

- Sturdy construction with levelling feet

- Below-surface filling with lance raise by weight or below-bunghole filling

- Very simple installation and easy to use

- Standard design with 2 weighing ranges

- Also available in stainless steel design

Drum filling systems

- Very cost-effective solution when it comes to realise only the filling process

- Sturdy construction with levelling feet

- Very simple installation and easy to use

- Filling mode can selected, either below-surface, below-bunghole or above-surface mode

- Control of customer’s product pump or pilot valve is included

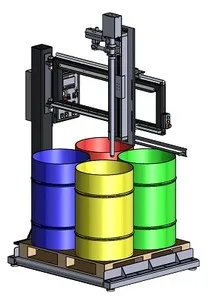

Pallet filling systems

- Very cost-effective solution as the whole controland operating modules are directly at the filling station

- Below-surface filling with lance raise by weight, below-bunghole filling or above-surface filling

- Appropriate solution if handling is possible only from the front

- Sturdy column construction

- Control of customer’s product pump or pilot valve is included