Load Cells

What You Need to Know About Load Cells

A load cell is an important part of industrial measurement and is a sensor used in various applications. It is designed to measure the force applied to an object and convert that force into electrical signals.

The function of a loadcell is quite simple but of great importance. For example, they are used in industrial weighing systems to accurately measure the weight of products.

They can be used to check the weight of a load on a belt conveyor and to calculate the center of gravity of a boat. The load cell operating principle is usually based on a series of deformation measurements. When load is applied, the resistors inside the load cell undergo deformation. This deformation is detected as a resistance change or a voltage signal and transmitted to the measuring instrument.

The use of load cell is preferred in weight and force measurement.

Load cells come in various shapes and sizes and can operate in different force ranges. They are also designed to be resistant to different environments. A load cell to be used in an industrial environment can be designed to withstand shocks, vibrations and extreme temperature changes.

A load cell sensor is a precision electronic device used to measure the weight or force of an object.

The load cell plays an important role in industrial measurement applications. It must be properly selected and installed to ensure precise and reliable measurements. They also require regular maintenance and calibration. However, when used correctly, a load cell can increase efficiency in industrial processes and significantly reduce operating costs.

How Does a Load Cell Work?

The working principle of a load cell generally relies on a series of deformation measurements and includes the following steps:

- Force Application: The first step is the application of a force to an object, typically involving weighing a load, lifting, or applying force on a machine.

- Deformation: When the force is applied, the load cell induces some deformation in its measuring elements. This deformation is based on the structural properties of the load cell and varies depending on the magnitude of the force.

- Electrical Signal Generation: Deformation causes a change in resistance or strain within the measuring elements of the load cell. This change is perceived as an electrical signal and transmitted to the measuring device.

- Signal Processing: The measuring device processes the electrical signal received from the load cell and converts it into a numerical value, representing the magnitude of the applied force.

- Data Reading and Analysis: Finally, the obtained numerical value is read and analyzed. This analysis is typically used to provide feedback to a control system or inform a user.

The document contains comprehensive information about different types of load cells and their applications, including platform, beam, suspension, ring, and others.

If you need a specific section translated in more detail, please let me know!

What Are the Types of Load Cells?

A load cell is produced in different types and structures to suit various applications. Here are some of the commonly used load cell types:

Platform Type Load Cell:

Platform-type load cells are typically used alone and have a wide capacity range. They are manufactured as if there is an imaginary platform on them and operate at maximum performance within the dimensions of this platform. These imaginary measurements are specified in the technical specifications of each load cell. They are widely used in industrial weighing systems and logistics applications.

Platform-type load cells are ideal for making reliable and accurate measurements in industrial weighing systems. Their features of durability, precision, and easy installation make them preferable in various industrial applications.

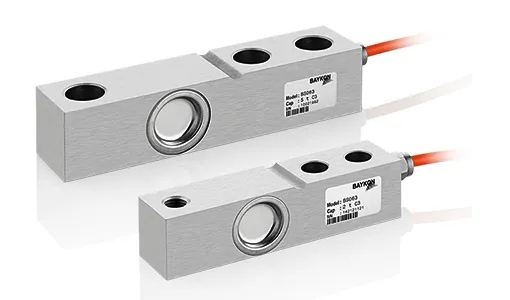

Beam Type Load Cell:

Beam-type load cells are particularly used in weighing applications with high capacities. Multiple beam-type load cells can be used within a single application. They are employed in high-capacity floor scales, tank and silo weighing, forklift scales, and specially designed mechanical structures.

With their long and narrow design, high capacities, flexible installation options, and high precision, they are practical for industrial applications.

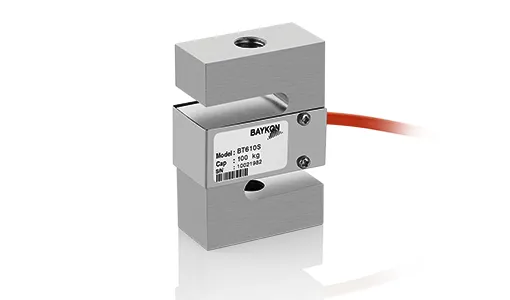

Tension Type Load Cell:

Tension type load cells are used to measure the downward force applied to a suspended object. These load cells are commonly used in lifting equipment, cranes, Tension systems, and industrial weighing systems. Additionally, in cases where raw material tanks are suspended, this type of load cell can be used with specific safety precautions.

Tension type load cells are essential for safely lifting and transporting heavy loads. With their high capacities, flexible installation options, and precise measurements, they are reliable and efficient in industrial applications.

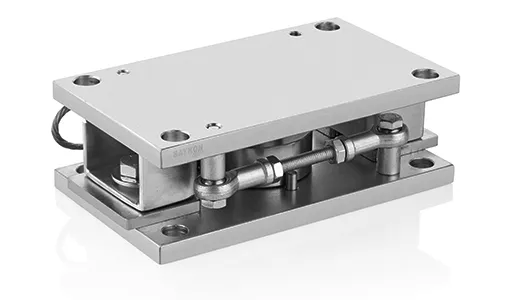

Double-Ended Shear Beam Load Cell:

Double-ended shear beam load cells provide more reliable and stable measurements thanks to their long and narrow design. These load cells are specially designed.

Reliability and stability are crucial in applications. These load cells are typically used in beams, lifting equipment, and industrial weighing systems.

Ring Type Load Cell:

Ring-type load cells are a special type of load cell characterized by their circular or ring-shaped design. These load cells are usually used to measure or suspend the load of circular objects. Ring-type load cells are widely used in industrial applications thanks to their high capacities, durability, flexible installation options, and high precision.

Compression Type Load Cell:

Compression-type load cells are load cells designed for use in special applications. They are employed in high-capacity weighing projects due to their structure. Typical applications include truck scales, tank and silo weighing, industrial processes, and test machines.

They allow you to make reliable and precise measurements with their accuracy, durability, flexible installation options, and wide usage area.

Bending Beam Load Cell:

Bending-type load cells are special load cells used in narrow spaces or applications with limited mounting areas. The bellows structure makes the load cell more flexible, allowing it to be easily mounted in tight spaces. This type of load cell is generally characterized by high precision and reliability. They are used in industrial weighing systems, lifting equipment, and many other applications.

Web Tension Type Load Cell:

Web Tension-type load cells are specially designed to measure the tensile force of a material. These cells are commonly used in industrial machines, such as in printing, film, and paper production, packaging, textiles, and cable machines.

Web Tension-type load cells are ideal for measuring tensile forces in industrial production lines. They offer high precision and flexible installation options and have a wide range of applications.

Rope Tension Type Load Cell:

Rope tension-type load cells are specially designed load cells for measuring weights on carrying materials such as ropes. These load cells are mounted on a rope or cable and measure the tensile force of the rope directly. They are generally used in cranes and other lifting equipment like elevators. Rope tension-type load cells are preferred for ensuring the safety of lifting equipment and accurately lifting loads.

Pin Type Load Cell:

Pin-type load cells are a special type of load cell commonly used in lifting and transport applications. These load cells are usually mounted inside a circular structure and measure the load carried by the pin when force is applied. Pin-type load cells are used in various load-bearing systems, such as bridge cranes, elevator pulleys, and ship cranes.

Pin-type load cells play a vital role in lifting operations to measure the load and ensure safety. They are ideal for making reliable and precise measurements in industrial lifting and transport operations. These products have high durability, precision, and flexible installation options.

Extensometers:

Extensometers are devices used to measure the mechanical stress and deformation behaviors of materials. They are typically composed of thin wires or strips placed on or inside the material's surface. These devices are used to analyze how a material behaves under stress, bending, tension, or pressure.

Extensometers are an essential tool in fields like material engineering, metallurgy, construction, the automotive industry, aerospace, and aviation. They are used to accurately evaluate and optimize the mechanical properties of materials.

Digital Load Cells:

Digital load cells are a new technology that converts the measurements of old analog load cells into digital form and transmits the data. These load cells process measurement data digitally, allowing for more accurate and reliable measurements. Digital load cells are used in various applications, including industrial weighing systems, lifting equipment, transportation vehicles, and automation systems.

With their advantages of precise measurements, easy integration, and data transmission, digital load cells are preferred in industrial weighing and control systems.

Exproof Load Cells:

Exproof load cells are a special type of load cell designed for safe use in explosive environments. The term "Exproof" indicates that equipment designed for use in explosive fields is protected against explosions. These load cells can operate safely in potentially hazardous areas with explosive gases, vapors, or dust.

Exproof load cells are used in industrial applications where explosive fields exist. These applications include the oil and gas industry, chemical industry, refinery plants, mining, and waste management. With their ability to perform safe measurements in explosive environments and certified design, they provide a solution that meets safety standards.

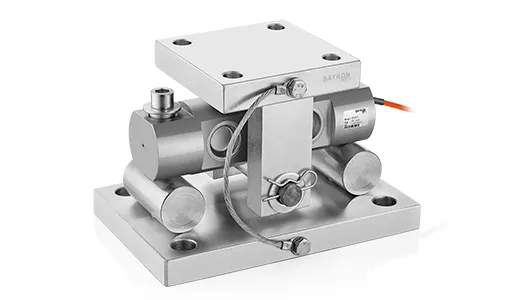

Load Cell Mounting Kits:

Load cell mounting kits are hardware and accessories that ensure the correct and safe installation of load cells. These kits typically include various parts designed to meet different mounting needs. Load cell mounting kits allow the load cell to be mounted correctly, ensuring reliable and accurate measurements.

Due to their features of flexibility, durability, and easy installation, they are widely preferred in industrial applications.

Load Cell Feet:

Load cell feet are specially designed accessories used to support and stabilize the mounting of the load cell. These feet are typically mounted under the load cell and are designed to fit various mounting surfaces.

Load cell feet ensure the load cell is mounted correctly, allowing for reliable and accurate measurements. The internal structure, rubber quality, and hardness of the feet are critical criteria for weighing applications. Flexible mounting options, durability, and easy installation make them essential.

Load Cell Junction Boxes:

Load cell junction boxes are specially designed boxes used to protect, organize, and direct the cable connections of load cells.

Junction boxes ensure that the load cell is securely and reliably connected, allowing for accurate and precise measurements. They offer features like cable protection, water and dust resistance, easy connection, and durability.

Why Should You Choose Baykon Load Cells?

- Quality and Reliability: Baykon is a brand with long-standing experience in industrial weighing and measurement equipment. It manufactures its products based on high-quality standards and the principle of reliability.

- Wide Product Range: Baykon offers load cells with various capacities and features, providing a wide product range to meet different application needs.

- Technological Innovations: Baykon continually updates and develops its products by following new technologies and innovations, enabling users to make more accurate, precise, efficient, and traceable measurements.

- Suitability for Industrial Applications: Baykon products are designed to be suitable for industrial environments. Their durable structures and appropriate protection levels provide reliable performance under challenging industrial conditions.

- Customer Support: Baykon focuses on customer satisfaction and provides support for product selection, installation, usage, and service, ensuring a reliable experience for customers at every stage.

- Competitive Prices: Baykon offers high-quality products at reasonable prices, giving customers a competitive advantage.

What is Load cell Calibration?

Loadcell Calibration is a process performed to ensure that load cells can make accurate and reliable measurements. This calibration process is performed to verify the actual measurement values of the load cell and correct them when necessary.

Load Cell Calibration is the process of making the measurement results given by the load cell accurate and reliable by comparing them with known reference weights. This process is necessary to improve the accuracy and precision of the load cell.

Calibration Process

The load cell calibration process usually includes the following steps:

1. Preparation: The load cell to be calibrated must be cleaned and in an environment suitable for the operating conditions. In addition, the necessary calibration equipment (reference weights, measuring instruments, etc.) should be ready.

2. Use of Reference Weights: A gradual load is applied to the load cell using reference weights with known weights. For example, weights with 0%, 25%, 50%, 50%, 75% and 100% load capacity can be used.

3. Data Collection: The measured values of the load cell for each reference weight are recorded. This data is analyzed by comparing it with the output signal of the load cell.

4. Calculation and Correction: The differences between the measured values and the reference weight values are calculated. These differences are used to make the necessary corrections to improve the accuracy of the load cell.

5. Documentation: The calibration process is documented. This includes the date of calibration of the load cell, the reference weights used, the measurement results and the corrections made.

Get the Best Load Cell Prices and Buy Load Cells…

For the most affordable load cell prices that fit your budget, you can call our sales team, fill out a form, or send an email to [email protected]. We are happy to offer you the best load cell prices and high-quality load cell options. Call us now to get a load cell price.