BX30Fill Filling Controller

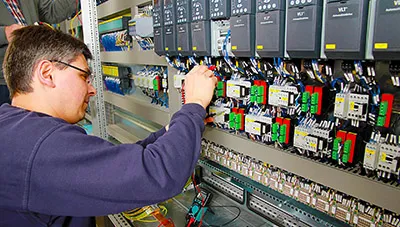

Baykon BX30Fill, Filling and Packing Controller is high tech, smart and economic instrument for usage at various filling and packing machines. Its configurable specific recipe build feature and smart filling algorithms give big advantages in usage.

The most common filling & packing applications fit one of its 12 filling modes. Master-slave operation provides the set up and recipe transferring to all BX30Fill slave controllers on the machine. Full control of multiscale bagging or packing machine is available.

BX30Fill has Recipe and ID memories having 250 records size each, for fillings with different materials and specific fillings like batch filling.

Its programmable 7 keys can be assigned to the predefined functions in order to provide quick and informative operation. Freely programmable digital inputs and outputs eliminates additional PLC requirement in the cabinet to control customers pump, pilot valve, nitrogen purging, rotary valve, bag inflator, material activator etc.

Programmable reserved I/O ports enable operation until receiving the new digital I/O board in case of any digital I/O malfunction.

Highlights

Measurement Type

Weight Measurement

Applications

Liquid Filling, Ventil Filling, Packaging, Bagging, Tank Filling/Discharging

Protection Class

IP67

Type of Device

Panel

Serial Communication

RS232, RS485, USB, Modbus RTU

Industrial Communication

Modbus TCP, Ethernet TCP/IP, Profinet, Profinet S2, Profibus, EtherCAT, EtherNet/IP, CANopen, Powerlink, CC-Link

Web/PC Access

Configuration by App, Data Collection

IoT

Yes

Digital Input & Output

Input, Output

Energy Supply

12V DC, 24V DC

Certificate

OIML, MID

Trade Approval

Yes

Other Features

Analog Feeding Speed Control, Alibi Memory, Data Logging, eCal, sCal, Multi-point adjustment

Functional Features

Main Features

• 12 different operation modes for the most common applications,

• Configurable recipe content,

• 7 Programmable keys,

• Digital I/O's: internal 12/14, external 16/16

• Spare I/O's to continue filling in case of any digital I/O malfunction

Smart Operation with

• Smart filling algorithms,

• Smart start-up the filling.

• Full control of bagging machines,

• Master-slave operation to transfer set-up to other instruments,

• Multicolor LCD to guide and warn the operator.

Advanced Technology & Performance

• High speed real time operation,

• Up to 1600 conversions per second,

• 1000 times higher filling control resolution than scale increment,

• Freely programmable digital I/O’s, timers and logic functions,

• Remote service via internet.

Integration & Connectivity

• Ethernet TCP/IP, USB, RS-232C, RS-485, Profibus, Profinet, Modbus RTU, Modbus TCP, EtherNet/IP, EtherCAT, CANopen, CC-Link, CC-Link IE, Powerlink

• DIN rail digital I/O unit for easy cabling in the cabinet.